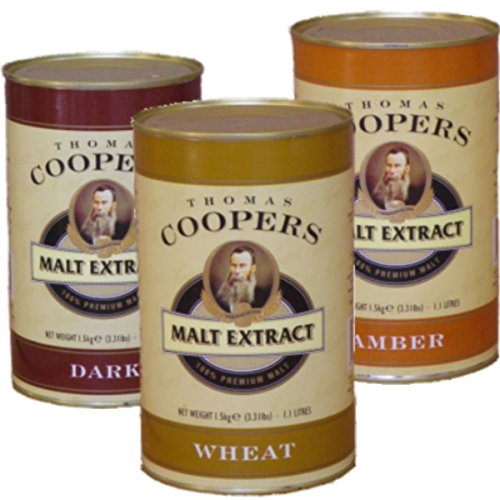

Malt Extract

When we looked at the brewing process we covered the steeping of the grains in the mash tun, this period, called mashing, is one you can bypass by using malt extract.

Mashing is a process which takes time and extra equipment so removing this process by using malt extract instead is often desirable. There are many commercial breweries and brewpubs that use malt extract, rather than choosing to mash grain in a mash tun themselves, for the very fact it saves time and provides consistent results every time.

Malt extract is made by soaking and rinsing malted barley, a process called mashing, that can take a couple of hours, to create a concentrated sweet liquid. Using malt extract saves you the time and expense of doing this yourself and will make the brewing process easier with less technical difficulties. Perhaps preferable for a first time brewer!

When buying malt extract for creating your own recipes it is a good idea to ensure you are purchasing unhopped malt extract because we will be adding our own hops during the brewing process. It also comes in two forms:

or

Either variety are fine for our purposes and can be used interchangeably simply by following the guidlines below:

How can I convert liquid malt extract (LME) to dry malt extract (DME)?

Liquid malt extracts are roughly 20% water so 1kg of liquid is the same as 800g of dry malt extract. If you want to convert a recipe that list LME then multiply the amount by 0.8 to achieve the amount of DME required. If your recipe list dry then divide the amount by 0.8 to reach the amount of liquid extract needed. For example

3kg of LME = 3 x 0.8 = 2.4kg of DME

3kg of DME = 3 / 0.8 = 3.75kg of LME