Reusing Yeast From One Beer To The Next

Reusing yeast isn’t a novel idea, in fact, in commercial breweries it’s the norm. A commercial brewery will reuse yeast by cropping the yeast from the top or bottom of a fermenter just after the primary fermentation has finished. The yeast can then be used in the next batch which benefits from large amounts of really viable yeast and a very short lag time before fermentation. In fact there are some breweries that take the concept to the extreme. A brewery in the US cultured yeast from a bug encased in amber and made a beer with it. It’s good to know yeast is hardy enough to survive 45 million years encased in amber, but, what are the practicalities of the home brew reusing yeast.

The example set by commercial breweries shows us home brewers a few important lessons with regards to culturing yeast and reusing yeast from previous batches. Reusing yeast is a great way to cut your brewing costs, especially if you use a lot of liquid yeasts that are more expensive as well as pitching large amounts of healthy, viable yeast. You can reuse the same yeast for around 4 – 5 generations of beer before having to purchase any new yeast so the savings stretch out for quite a while.

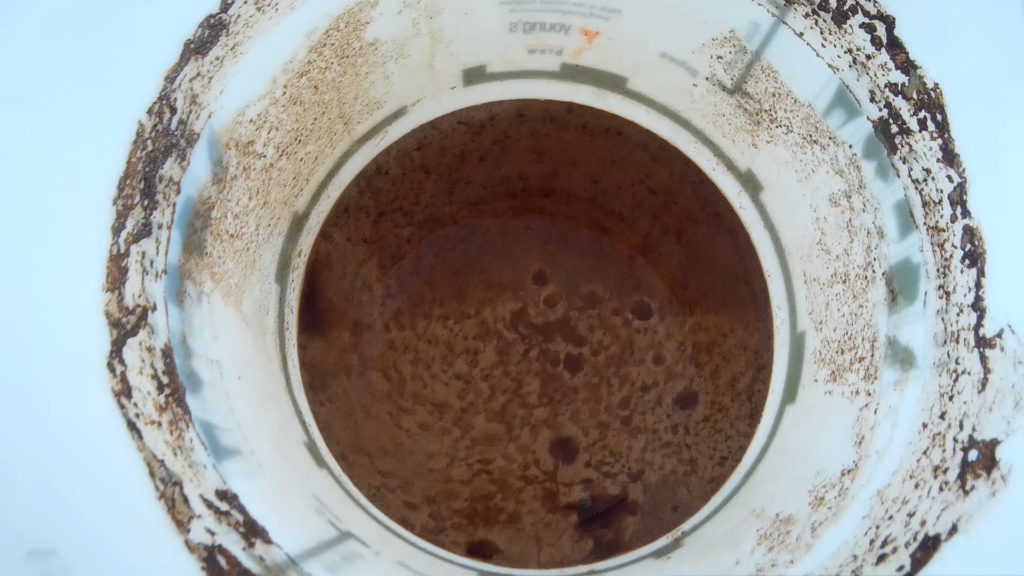

Reusing Yeast Slurry

The easiest way to reuse yeast is to brew beers consecutively, one after the other. When you move the beer from a primary to secondary fermenter or to bottles you can see a whole lot of yeast that is still viable to brew with. An easy way of reusing it is to ahead and put another batch of beer on the used yeast slurry, so really you need to brew a beer the same day you rack your original to secondary and siphon the new beer directly onto the yeast cake. All that should be required is a gentle rousing of the yeast by shaking or stirring the fermenter and fermentation should begin quickly.

The only issue with reusing yeast like this really is the huge amount of yeast and trub left after the fermentation of the initial beer. You can sometimes have up to an inch of sediment which includes hop particles and trub in your fermenter after primary fermentation and pitching a new batch on top of it only increase the amount of yeast and trub further. I would only really use this technique for a beer that will be out of primary quickly i.e a lower ABV beer, so as to not cause any off flavours from the excessive amounts of yeast and trub.

Just like pitching too little yeast can have an impact on the quality of a beer, pitching too much yeast can also have an affect on the flavour. This along with the other debris from the previous batch of beer makes reusing yeast in this way a lot less desirable.

Alternatively, this is my preferred method of reusing yeast. After primary fermentation of you starting beer siphon out as usual and leave half an inch of beer in the bottom. Give the fermenter a swirl to get some of the yeast slurry into suspension. You will then be able to pour these into a sanitized jar or container and place a cover on for the first few days, a piece of sanitised foil secured with a rubber band will allow CO2 generated by the yeast to escape. After a few days you can put a lid on but do keep an eye and vent any carbon dioxide that may build up

Storing Yeast Slurry

You will need to keep an eye on these for the first few days and vent the container so no excess of CO2 can build up in the storage containers. You can keep these yeast slurries in the fridge for up to 4 – 5 weeks before reusing. When it comes round to reusing take them out of the fridge the day before to warm to pitching temperature. If you are reusing the yeast after a relatively short time then I usually pitch directly into the new batch. If the yeast has been stored for more than a few weeks you may want to consider making a yeast starter to test the viability and health of the yeast slurry.

To round things up, I will give you a few tips on successfully reusing yeast:

1. Make sure absolutely everything is sanitised. Use a good sanitiser and be through. If wild yeast or bacteria get in then you will ruin a whole batch. This of course is the most important part of making beer. If there is a problem with your sanitation from the previous batch of beer and you are repitching the slurry into your next batch you are in effect inoculating the beer with bacteria that will spoil it.

2. Only reuse yeast up to 4- 5 generations. Over time the yeast will begin to alter and fermentation may be affected, this can be something as simple as the behaviour of the yeast will change, it may not attenuate fully or flocculation may change.

3. If you are reusing yeast always go from light beers to dark beers, or from low alcohol to high. You don’t want to brew a 8% ABV beer then reuse the yeast for a 3.5% session beer. Ideally you should brew the weaker beer then work the yeast up to brewing a stronger beer reusing the same yeast.

If you are brewing a dark beer like a stout or porter and pitching the yeast into a light beer, it may affect the colour and flavour ever so slightly as if you are doing this just be aware that it may actually be better to wash the yeast before reusing.

4. Just to reiterate, keep everything sanitized.

Leave a Reply

Want to join the discussion?Feel free to contribute!